How Does Plastic Extrusion Works?

Plastic extrusion is a fascinating manufacturing process that takes raw plastic materials and crafts a wide range of products. In this blog, we’ll explore the intricate journey of plastic extrusion, from the initial pellets to the final, versatile products.

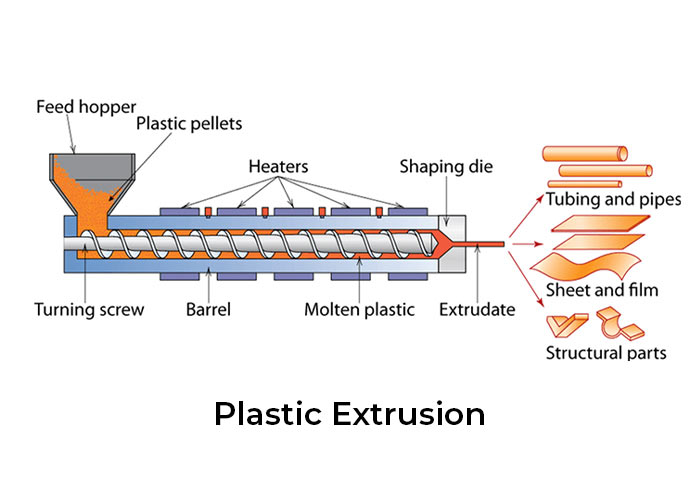

The Process: Our journey begins with the hopper, where carefully chosen plastic pellets await their transformation. These pellets are selected for their ease of processing and are gravity-fed into the next stage.

Heating and Melting: Inside the extruder barrel, the plastic enters a world of controlled heat. Multiple temperature zones gradually melt the plastic as it progresses from the feed throat to the die.

Screw Propulsion: A continuously rotating screw within the barrel propels the molten plastic forward. The screw not only provides propulsion but also generates additional heat, optimizing the extrusion process.

Purification and Pressure: Before leaving the barrel, the molten plastic passes through a screen supported by a breaker plate. This screen filters out impurities and maintains internal pressure, ensuring a high-quality final product.

Taking Shape: As the plastic is forced through the die , it emerges with the same shape as the die opening. This marks the culmination of the extrusion process, resulting in the intended product.

Cooling and Setting: The freshly formed product undergoes rapid cooling in a water bath or through cooling rolls, solidifying its shape and dimensions.

A Journey Through Time

The roots of extrusion date back to Germany, where Paul Troester pioneered the first plastic extruder. Since then, while the basics of the process remain unchanged, significant advancements have improved efficiency and capabilities.

Today, plastic extrusion is a versatile and efficient manufacturing process, capable of handling a wide range of plastics. Custom plastic extrusion has evolved to meet the demands of modern industry, delivering quality and consistency.

In conclusion, plastic extrusion is an artful blend of science and creativity, where precision and innovation transform basic plastic pellets into a diverse array of products. Umiya Engineeers has mastered the making of spare parts like screw, barrels, die head and, etc. We have pushed the boundaries of what’s possible with plastic extrusion machine parts. Join us on a journey of discovery in the world of plastic extrusion.